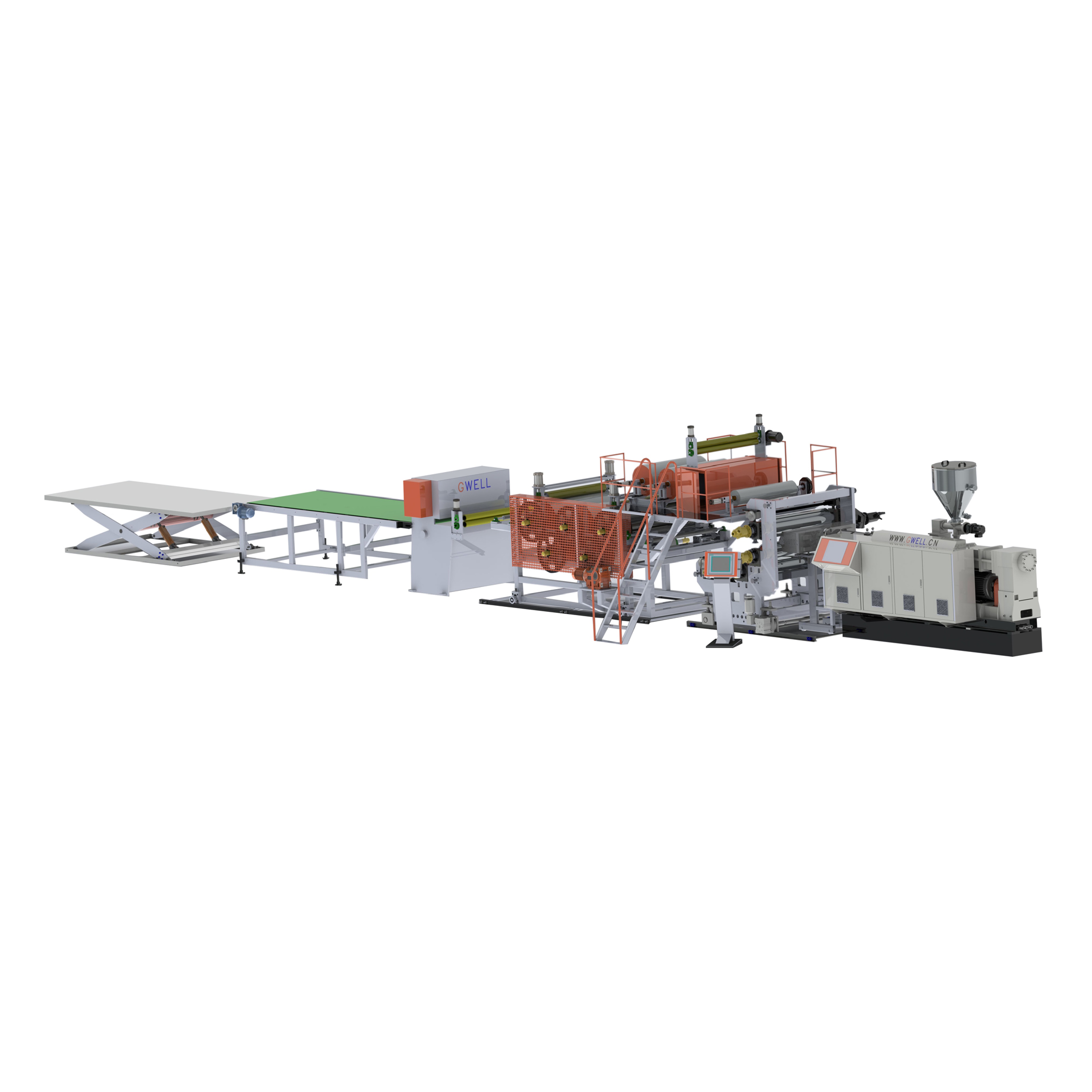

SPC floor extrusion machine

SPC floor one step extrusion line

SPC flooring: Stone Plactic ComPosite is also short for hard PVC flooring sheet

SPC floor is produced by conical twin-screw extruder, through three or four roll calender, laminating PVC color film, PVC

wear-resistant layer and PVC substrate at one-time. The process is simple, easy to operate, the lamination is completed by heat, no glue is needed. SPC stone plastic floor, is based on high-tech development of a new type of environmental protection floor, with zero formaldehyde, mold, moisture, fire, insect prevention, simple installation and other characteristics. SPC floor material uses environmental protection formula, and it does not contain heavy metals, phthalates, formaldehyde and other harmful substances. In Europe, the United States and the asia-pacific market, it is widely popular. With its outstanding stability and durability, stone plastic floor has solved the problem of real wood floor being affected by damp, deformation and mildew, and solve the formaldehyde problem of other decoration materials. It can choose many design and color patterns, suitable for indoor decoration, hotels, hospitals, shopping malls and other public places.

GWELL special technology can meet the requirements of SPC floor synchronous pattern production, shrinkage after tempering

treatment: ≤1‰, shrinkage without tempering treatment: ≤2.5‰ (shrinkage test standard: 80℃, standard for 6 hours)

SPC floor is a new environment-friendly composite material product with the following advantages:

(1) good processability, can be ordered, planed, sawed, drill, surface can be painted.

(2) good sound absorption effect, good energy saving, indoor energy saving up to 30%.

(3) anti-insect, anti-termite, effectively eliminate insect harassment, extend the service life.

(4) strong plasticity. It can be very simple to achieve personalized modeling, and fully reflect the personality style.

(5) simple installation, convenient construction, do not need complex construction process, save installation time and cost.

(6) high fire resistance. Effective flame retardant, fireproof class B1, self-extinguishing in case of fire, and do not produce any toxic gas.

(7) no crack, no expansion, no deformation, no maintenance and maintenance, easy to clean, save later maintenance and maintenance costs.

(8) it is colorful and has many colors to choos. It has natural wooden texture and wooden pattern, and it can be customized the color according to customers' requirements.

(9) waterproof and moisture-proof. The basic solution to the moisture and water absorption of wood products in the environment is easy to rot, expansion and deformation, and it can be used in the environment in which traditional wood products can not be used.

(10) high environmental protection, pollution-free, and recyclable. Product does not contain benzene and formaldehyde. Recycled products greatly saves the amount of wood, so it is suitable for sustainable development of the national policy, and benefit the society.

Contact: Vivian Wong

Phone: +86 18861951768

Tel: +86 18861951768

Email: saleb@gwell.cn

Add: NO. 69 Hongrong Road,Chongchuan District, Natong, Jiangsu, China

We chat